Meeting the shortage of skilled workers through vocational training

A study cited by the Handelsblatt fears that the German economy will lose more than 500 billion euros in revenue by 2030 due to a shortage of skilled workers. Industry can only counter this by further increasing automation. But for this it requires technicians who can design, programme, commission and maintain production plants – in other words, specially trained experts.

But how can you learn automation technology? The best way is to build and programme an automatic production plant. But no company can afford to use its plant, which it needs for production, for teaching purposes. That is why Christiani, a company based in Constance, aims to help educational institutions and companies to teach technical subjects. The modular mechatronics system (mMS) is used in automation technology.

Learning with the modular mechatronics system from

The modular mechatronics system looks and functions like a “real” plant. It features machines, conveyor belts, sensors and robots – everything just like a real plant, but much smaller. The high-bay warehouses do not contain heavy workpieces, but cubes made of plastic. The conveyor belt is narrow and the robot only lifts light weights, but the sorting unit can distinguish components like an industrial unit.

The control system is based on a Simatic S7, modern industrial sensor technology is integrated throughout the system and the IOT functions can be controlled via a dashboard. With this modular mechatronics system (mMS) from Christiani, companies and educational institutions can impart solid knowledge in automation technology and mechatronics in a small space – from the basics to complex topics of Industry 4.0.

And now even with professional software for factory planning and simulation

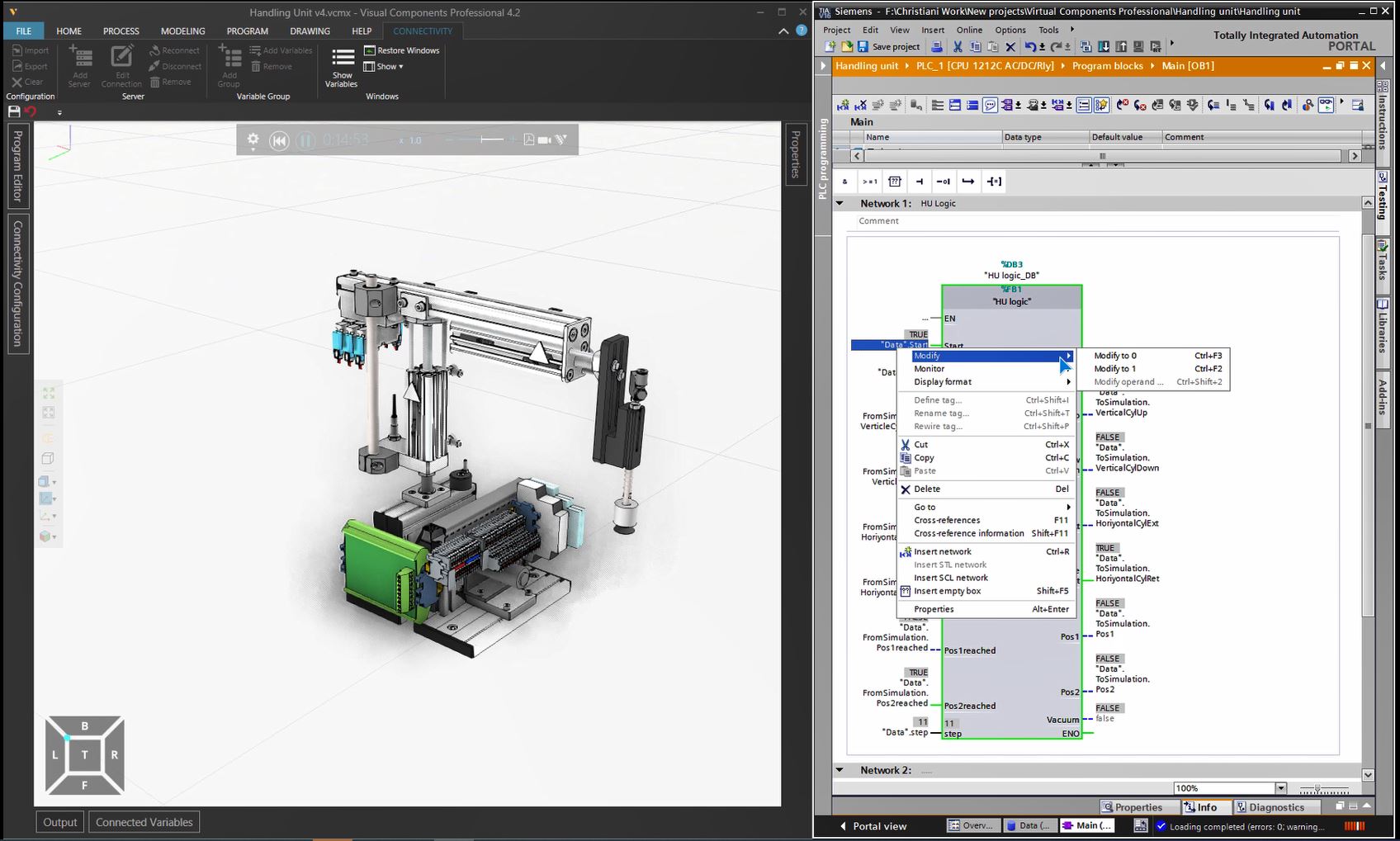

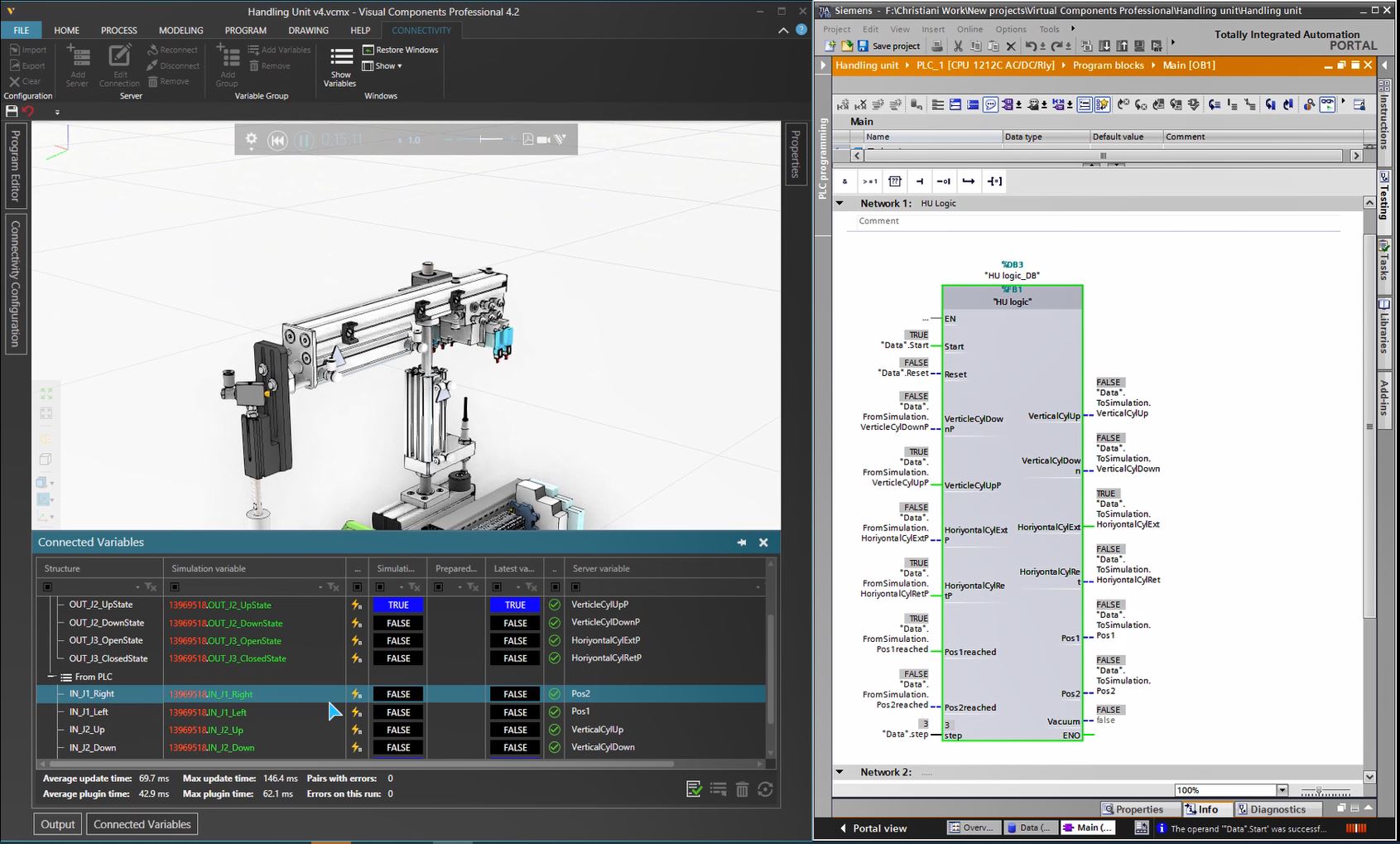

And now, brand new: as in the planning of real production plants, a solution is available that teaches the trainees how to plan and simulate a production plant. They first design, test and simulate the set-up in the virtual environment before converting it to a real plant – just like it is done in industry as well.

This system, called mMS-Sim4edu, is based on an industrial manufacturing simulation, namely the Visual Components system, a manufacturer from Finland that is one of the world’s leading suppliers of factory simulation software.

Planning with factory components from the included library

With Visual Components – and in the same way with mMS-Sim4edu – you can design, plan and simulate a plant using factory components, i.e. machines, robots, conveyor belts, etc. In order to achieve rapid use in training, the software is delivered with a prepared library. In the industrial version of Visual Components, the library contains factory components from well-known manufacturers in the field of automation technology; in the case of the mMS-Sim4edu training software, the library components are, of course, the functional modules of the Christiani mMS system such as robot stations, sorting units, high-bay warehouses, handling devices and conveyor belts. For example, the “digital twin” of the mMS assembly machine exactly simulates the behaviour of the real assembly machine. All physical limits of the real assembly are mapped in the computer model.

Detect and avoid problems earlier with Visual Components

This allows trainees to quickly and easily create layouts by dragging components from the library directly into the 3D environment and connecting compatible components such as conveyors using the plug & play function. Afterwards, they can simulate the flow of the entire plant on the screen and compare the capacity of different variants, calculate the size of buffers, determine the exact placement of robots, etc. In general: with the Visual Components software, the trainees can learn how to build a digital twin of a plant and use it to detect and avoid all kinds of problems earlier.

The trainees can present the results of the simulation as simulation statistics with line, area, bar or pie charts. In the statistics dashboard, they can create, modify and visualise individual simulation data. And if more in-depth analysis is required, simulation data can be easily exported to PDF or Microsoft Excel data formats. Trainees can also present their solutions as a video, 3D PDF file, 2D drawings or even in virtual reality models.

Practice-oriented training thanks to professional software

In Visual Components, Christiani has been able to gain one of the world’s leading providers of factory planning and simulation software as a partner. Visual Components is headquartered in Finland; its solutions have been used worldwide for over 20 years, by larger companies such as KUKA, Rehau or AGCO (Fendt) as well as by numerous smaller companies. Visual Components’ software is easy to use, visual and powerful. It can be used to transfer tasks and activities from the real environment to the digital environment. Trainees can develop, test and simulate manufacturing solutions in a networked environment. Bottom line: With mMS-Sim4edu, they get hands-on training.

© Dr.-Ing. Paul Christiani GmbH & Co. KG