The Sorting System Compact 4.0 – Our Solution for Industry 4.0

Lift the Quality of Your Vocational Training on the Next Level

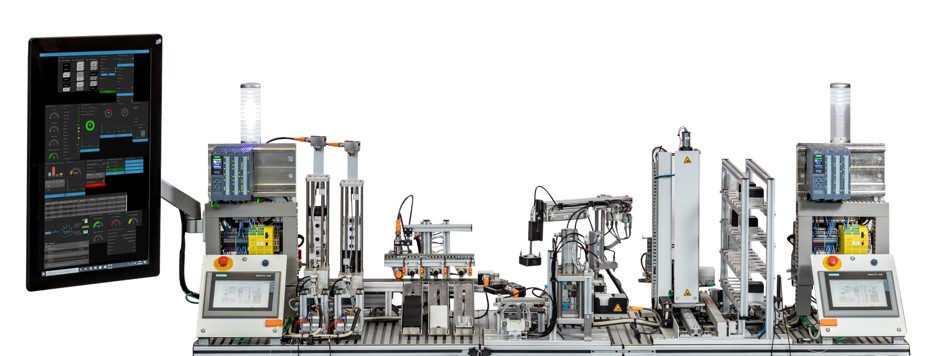

The new dimension for the knowledge transfer in automation technology. With the modular mechatronic system Sorting System Compact 4.0 (SSC 4.0), you can teach automation and mechatronics in a small space, from the basics to complex Industry 4.0 topics.

Modular Mechatronic Training at the Highest Level

The mechatronic system represents an industrial production process in small format. In the production process, the system manufactures end products from cube halves and stores them. The aluminium and plastic cube halves can be assembled in various combinations using spring pins.

The whole system consists of two stations, which work autonomously and can be operated separately.

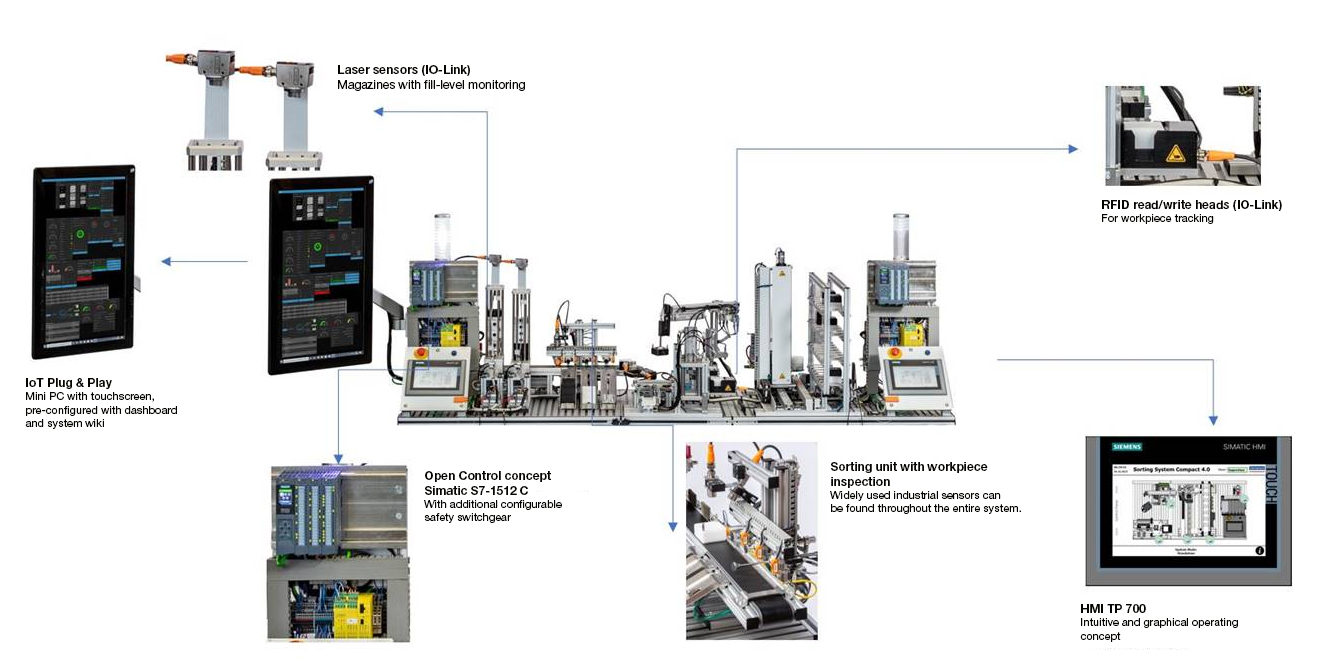

The Sorting System Compact 4.0 presents the special features of networked production and Industry 4.0 in a comprehensive and particularly practical way. Equipped with Christiani’s mMS modules and innovative software, the system represents a new generation of training systems for vocational training and further training in the field of automation technology.

Welcome to the age of Industry 4.0! The specially developed dashboard makes data collection and analysis very easy. In combination with the intuitive operating concept, the system offers the best conditions for successful know-how transfer. Even inexperienced users will be able to quickly understand the interconnections of networked production.

With the Sorting System Compact, you and your trainees start into the world of Industry 4.0 via plug and play.

- Continuous teaching system for the production of cubes – from separation to storage

- Including MES, Dashboard and Wiki

- Open concept, all components freely accessible

- Expandable to SmartFactory

- 11 assembly modules incl. storage and retrieval station

- Safety functions category 4

- OEE functionality as standard

- WLAN antennas included

- With original components from renowned manufacturers

- PC with Dashboard, Manufacturing Execution System (MES) and System-Wiki

- Divisible into two separate stations

- Plug & Play: Ready to use

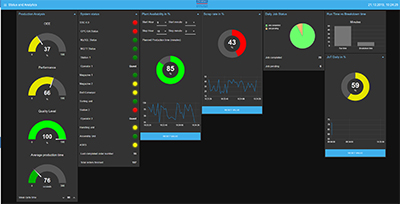

Everything, at a Glance at Any Time

With the help of the dashboard, the relevant production data of the modular Mechatronic System can be displayed on a graphical user interface in a clear and easy-to-understand way. Thus all processes are well monitored and the data is collected quickly and easily.

Evaluations and Analyses on PC, Tablet or Smartphone

All important information about the system is available in real time on the end device of your choice. We deliver the system with a data evaluation predefined by us. The dashboard can be configured individually according to your requirements. You can easily access and evaluate specific information such as magazine fill level, system pressure (pneumatic) or the production time of individual cubes. Only open source products were used for programming. Therefore you as a customer do not expect annual costs.

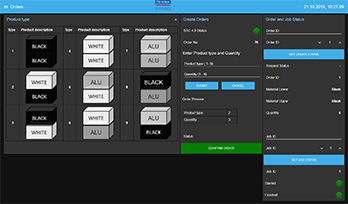

Order Management from Anywhere

You are currently not connected to the system, but want to retrieve information or place an order? No problem!

You can simply access the dashboard via your web browser and activate your production process at any time. With the appropriate setup, you can also access the system via the Internet from anywhere in the world at any time.

The Plant Wiki

The plant Wiki is also included in the scope of delivery and, like the dashboard, is pre-installed. In the Wiki you can find all relevant information about the system and the technologies used in it at any time. Here, we have also used open systems, so that the user can add further information at any time. This enables you to create your own learning platform.

Do you have any further questions?

We will be happy to advise you on which solution is best suited for your company or educational institution.